What is GGBS?

GGBS, or Ground Granulated Blast-furnace Slag, is a cementitious material that's mainly used in concrete to increase strength. This is obtained by quenching molten iron slag (a by-product of iron and steel-making) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder.

About EkoBlend GGBS

EkoBlend GGBS is a testament to innovation and sustainability in the construction industry, offering a groundbreaking solution in the form of Ground Granulated Blast Furnace Slag (GGBS). This versatile binder is utilized as an additive to cement, harnessing its latent hydraulic properties to produce Portland blast-furnace cement or blast-furnace cement.

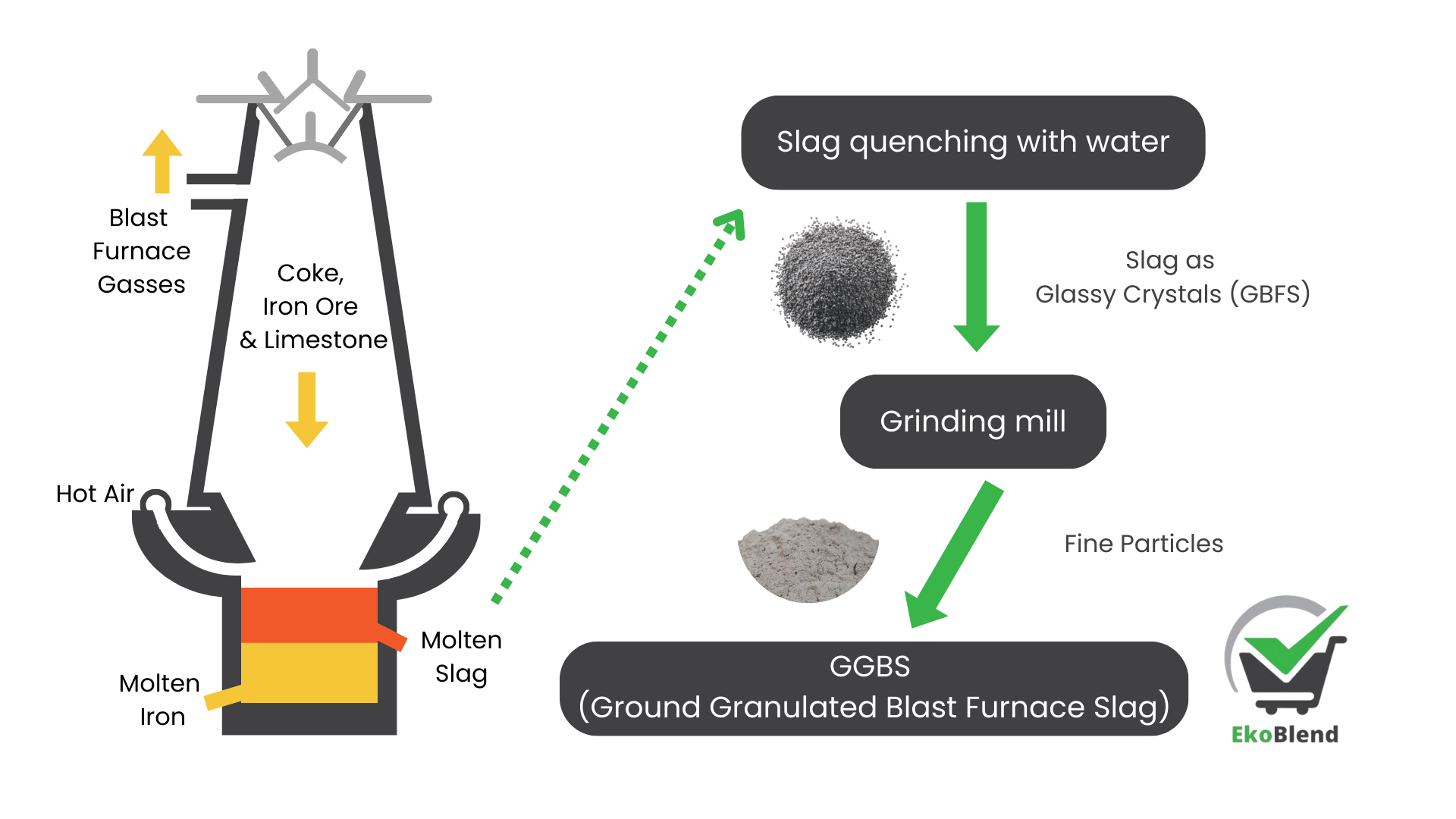

How EkoBlend GGBS is manufactured

Ground granulated blast-furnace slag (GGBS) is a by-product of iron manufacturing that is obtained by quenching molten iron slag from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powder. The process involves cooling of the slag through high-pressure water jets, which enables the formation of granular particles. The granulated slag is further processed by drying and then grinding in a vertical roller mill or rotating ball mill or roller press to a very fine powder, which is called GGBS.

Why EkoBlend GGBS?

Tech Specifications

375

Fineness, m2/kg

74

7 days Slag Activity Index (%)

7.8

Residue by wet on 45µ (%)

89

28 days Slag Activity Index (%)

96.3

Glass Content

Trusted By